Gate Valve

图文详情

GATE VALVE

MANUAL

1.APPLICATION AND PERFORMANCE CRITERION

1.1Application

This product is mainly used to opening & closing on gas and liquid medium pipelines to connect or cut off the flow of the medium. It is not suitable for regulating the flow of the medium. It has the advantages of small flow resistance and labor-saving opening and closing.

|

|||||||||||||||||||||||||||

|

The temperature in the table refers to the temperature of the pipeline medium in the working state and the pressure in the table is the continuous non-shock pressure.

-

- APPLICABLE STANDARDS

1.Design & Manufacturing Standard in According to API 600 2.Face to Face According to ASME B16.10

- Flange Connection Standard According to ASME B16.5

- Test & Inspection According to API598

- Pressure-Temperature Standard According to ASME B16.34

- STRUCTURE CHARACTERISTIC AND APPLICATION PRINCIPLE

1.Structure

-

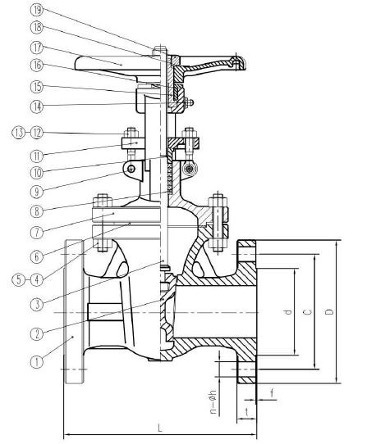

- Body 2. Disc 3.Stem 4. Bolt 5. Nut 6. Gasket 7. Bonnet 8. Packing 9. Pin 10.Gland 11.Packing Cover

- Eye Bolt 13. Nut 14.Oil Cup 15. Stem Nut 16.Glard Nut 17. Handwheel 18. Nameplate 19.Nut

- This valve achieves the purpose of opening and closing by rotating the handwheel to lift the valve stem and drive the disc to make a linear displacement perpendicular to the fluid.

- The handwheel rotates clockwise to close the valve (the handwheel has mark)

- Wedge-type flexible disc is adopted, with small closing torque, easy to seal and it is not easy to cause wedge dead due to temperature changes.

- The body is welded on the sealing structure, which can assist the packing sealing and facilitate maintenance.

- The upper part of the bonnet is equipped with an oil cup, which is filled with lubricating oil to lubricate the valve stem nut.

- The sealing surface is welded with wear-resistant material to enhance sealing performance and improve service life

- There are NPT 1/2 screw holes on the bonnet for users to connect the pressure relief device in the middle cavity (when ordering, must be specified)

- MAIN PARTS MATERIAL

|

Parts Name |

Body & Bonnet & Disc |

Upper Seal Seat of Stem |

Surfacing material for sealing surface |

Packing |

Gasket |

Stud |

Nut |

|

Material |

WCB/CF8/CF8 M/2205 |

F6a/F304/F316/F 51 |

13Cr/304/316/2205/ STL |

Flexible Graphite/PTFE |

Stainless Steel with Flexible Graphite Spiral Wound Gasket/Steel Ring |

A193 B7/B8 /B8M |

A194 2H/8/8 M |

- STORAGE, INSTALLATION, APPLICATION AND INSPECTION

1.STORAGE

-

- The valve must be stored in a dry and ventilated room, placed neatly and the valve stem should not be stressed.

-

- During the storage period of the valve, it should be in a closed state, and the flanges at both ends should be covered by plug.

- During storage of the valve, the stem threads and machined surfaces should be coated with an easy-to-remove rust inhibitor.

- Valves that have been stored for a long time should be regularly inspected, cleaned of dirt and coated with rust inhibitor.

2.INSTALLATION

- The valve can be installed in the horizontal position, but attention should be paid to the convenience of maintenance and operation (other positions must be specified when ordering).

- Before installation, it is necessary to carefully check whether the valve logo and nameplate conform to the requirements of the working conditions

- When installing the valve, it should clean the inner cavity and sealing surface, check the sealing surface, bolt connection, packing compression, and whether the valve stem rotates freely.

- The handwheel and transmission mechanism are not allowed to be used for lifting 5.When installing, tighten the connecting bolts evenly and symmetrically

6.After installation, the valve must be fully opened for pipe purging and system pressure test

3.APPLICATION

- The operating conditions of this valve must conform to the specifications on the nameplate and operating instructions.

- When the valve is used, it only can be fully opened or fully closed to prevent damage to the sealing surface when it is used to adjust the flow.

- When opening the valve, the apex of the valve stem is used as the fully open sign, that means the position that cannot be opened is used as its fully open position. In order to consider the lock hole phenomenon caused by temperature changes, it is usually opened to the apex position, and then back to 1/2

~1 turn as the fully open valve position.

- When the valve is running, the lubrication oil should always be applied to the trapezoidal thread and stem nut.

- The valve opens and closes the gate by rotating the handwheel and shall not rely on other auxiliary levers or power

4.INSPECTION

During the valve running, the following items should be checked regularly and the problem should be repaired in time.

- Whether the fasteners are uniformly strong

- Whether the packing is seriously worn and whether the gasket is damaged (stop the operation for maintenance)

- Whether the handwheel is light and flexible

- Whether the stem threads and stem nut are severely worn or deformed (stop the operation for maintenance)

- Whether the sealing surface is damaged or severely worn (stop the operation for maintenance) 6.Whether there is leakage at the connection between the seat and the body (stop the operation for

maintenance)

- Whether the body is severely corroded or worn, causing the body to become significantly thinner or even leaking, if these phenomena occur, it should be scrapped (stop the operation for maintenance).

- After the valve is repaired and assembled, the pressure test must be carried out according to the corresponding standards and the situation should be recorded after each inspection for future reference.

- MALFUNCTION AND ELIMINATION METHODS

|

Malfunction |

Reason |

Elimination Methods |

|

Packing leakage |

|

|

|

Leakage at the connection between the valve body and the bonnet |

|

|

|

Sealing surface leakage |

|

|

|

The handwheel is inflexible or the disc cannot be opened and closed |

|

|

7.CAUTIONS

-

- The user is responsible for the selection of valve material and its possibility of deterioration in use and the necessary periodic inspection.

- The valve design only considers general working conditions, if there are special requirements, it must be specified in the contract.

- The design of this valve only considers slight corrosion. For the occasions with severe or special corrosion, this valve is not suitable for use.

- The operating temperature range shall not exceed the provisions in Article 1.2, and the consequences caused by exceeding (including instantaneous) this range are entirely the responsibility of the user.

- The maximum working pressure of the valve at the corresponding temperature shall not exceed the provisions in the table of Article 1.3. The consequences caused by exceeding (including instantaneous) this range or using a pressure rating not corresponding to the temperature are entirely the responsibility of the user.

- The applicable medium of this valve is listed in the table of Article 1.2, the consequences beyond this scope are entirely the responsibility of the user.

- This valve is a double-seat valve. When the valve is closed, there may be residual liquid in the body cavity. During the heating of the system, the residual liquid may be heated and cause abnormal increase in the pressure of the body cavity. This valve does not take measures to relieve pressure and the user can discharge the residual liquid by partially opening the valve or other methods during subsequent system startup.

- The temperature of the body surface during the valve working process may cause human body contact burns and the user must set warning signs on the corresponding parts.

- The valve shall not increase or replace the packing under pressure, and the upper sealing structure is not the reason for the user to replace the packing under pressure.

- Welding repair and exterior painting shall not be allowed during valve operation. 10.The valve can not be disassembled under pressure.

- During repair, the repairing material needs to be matched according to the Article 4.

- The design of this valve has not carried out life calculation & test and fatigue strength check, so during use, the user must regularly repair and replace it.

- The design of this valve does not consider the seismic load and the manufacturer is not responsible for the consequences arising therefrom.

上一页

无

下一页

Related Products

Messages